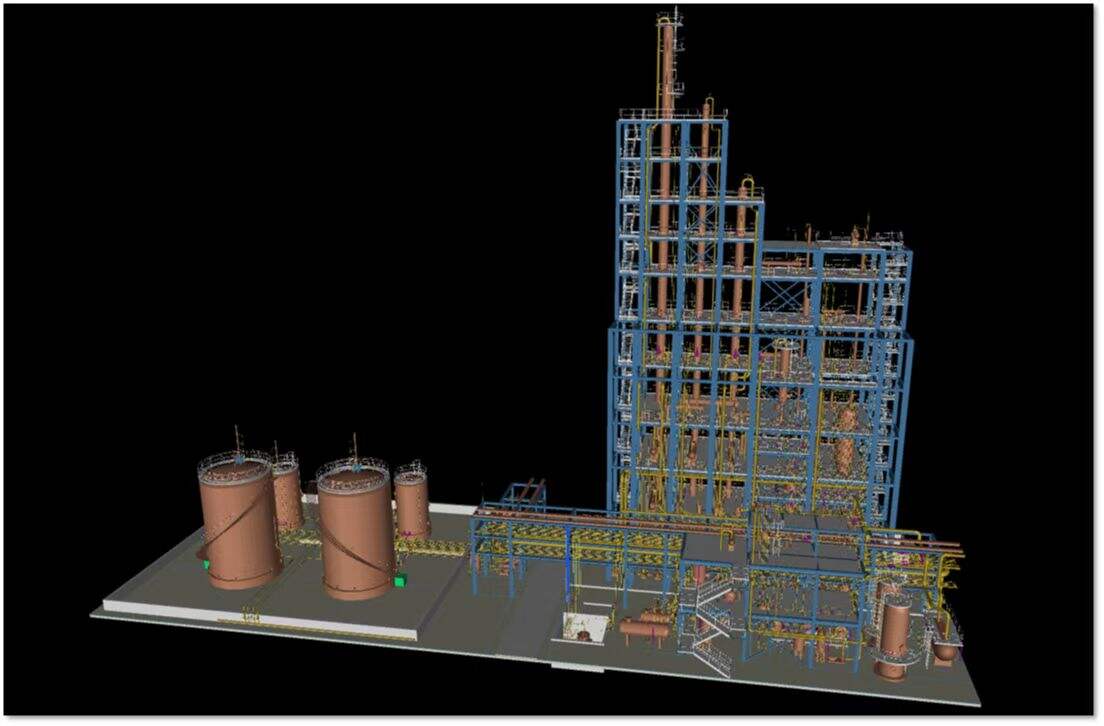

The endeavors our clients undertake and the issues that need to be solved with chemical engineering distillation column design services include a wide range of industries. It allows us to create designs that will enhance the distillation, but it includes elements such as elevating energy consumption or selection of materials that are friendly towards the environment. Our approach eliminates the negative aspects of project turnaround life cycle storing as much as possible the covering approaches, norms and standards aiming producing satisfying industry design.