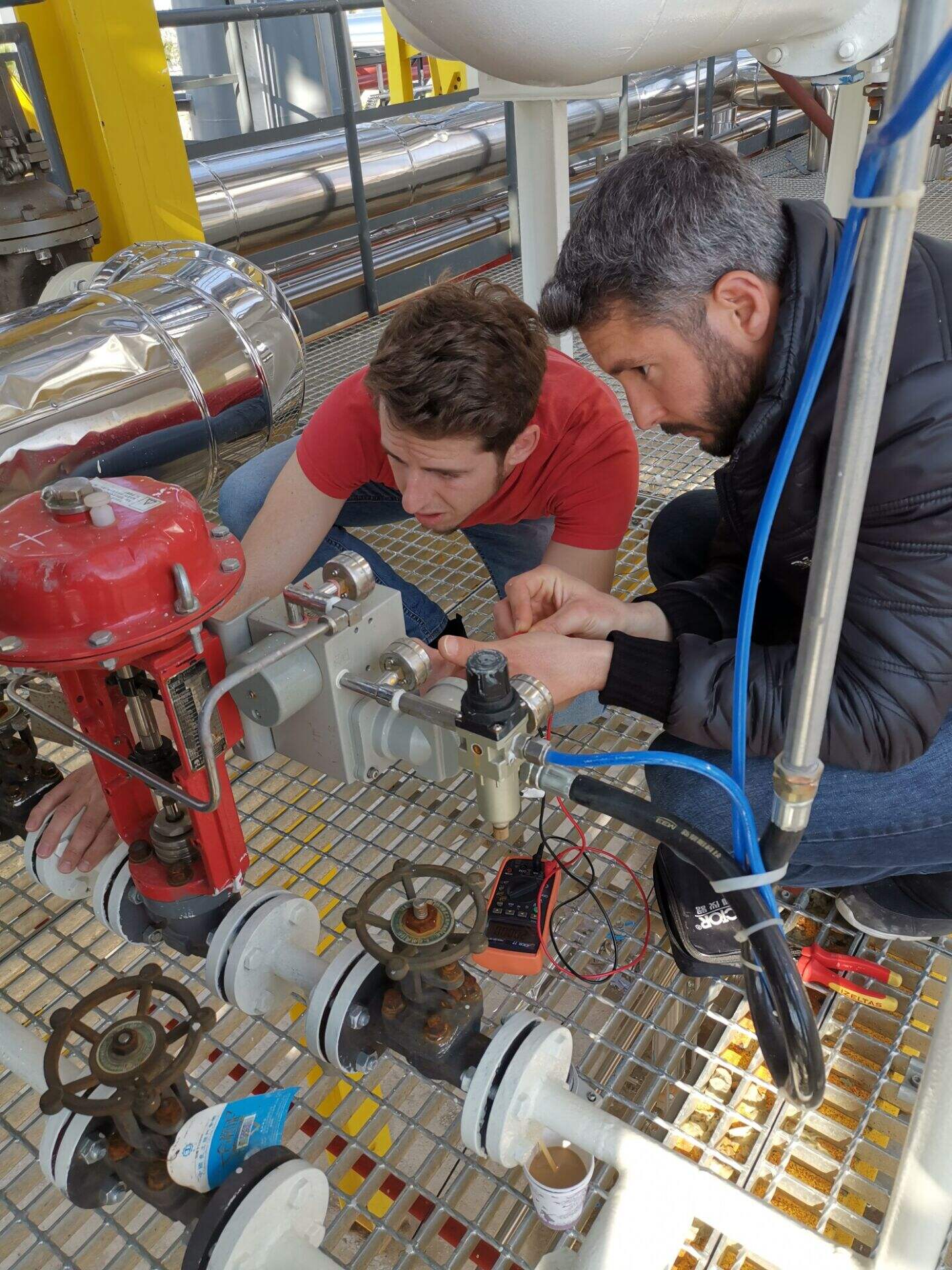

In terms of chemical plant operation, our activities start from almost any stage because our guidance is professional and integrated with focus on safety. We can make recommendations on improvement of processes, appropriate equipment and legal requirements to be met. Our teams take on clients from the start and continue to service the plants as long as required for them to be running efficiently. With all of the aforementioned and most importantly our clients’ trust, we assist in achieving targeted plant operational goals while losses and expenditures are minimised.