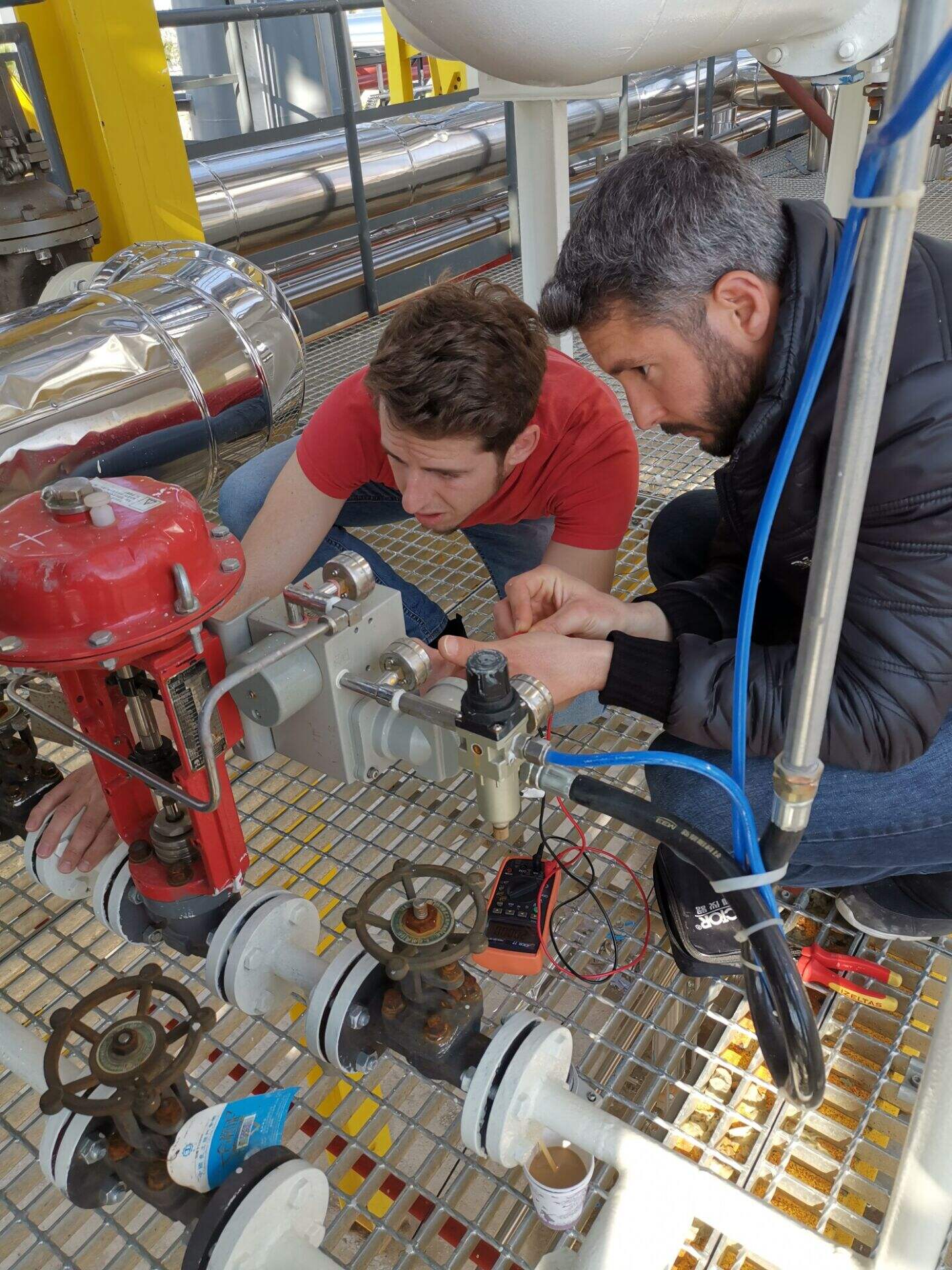

At Sanli Tech, we understand how critical the maintenance of moving parts of the chemical equipment is for the successful working of the chemical plant. The primary goal of our onsite assistance services is to assist you in making certain that your equipment is functioning at its optimum level. So as to achieve this, we approach the problem by integration of modern technologies and well tested techniques that are aimed at troubleshooting potential risks before they become problematic and this way, the reliability and the efficiency of all your processes are maximised. Our methods are culturally relevant and flexible, seeking to address the multifaceted requirements of the international market.